Description

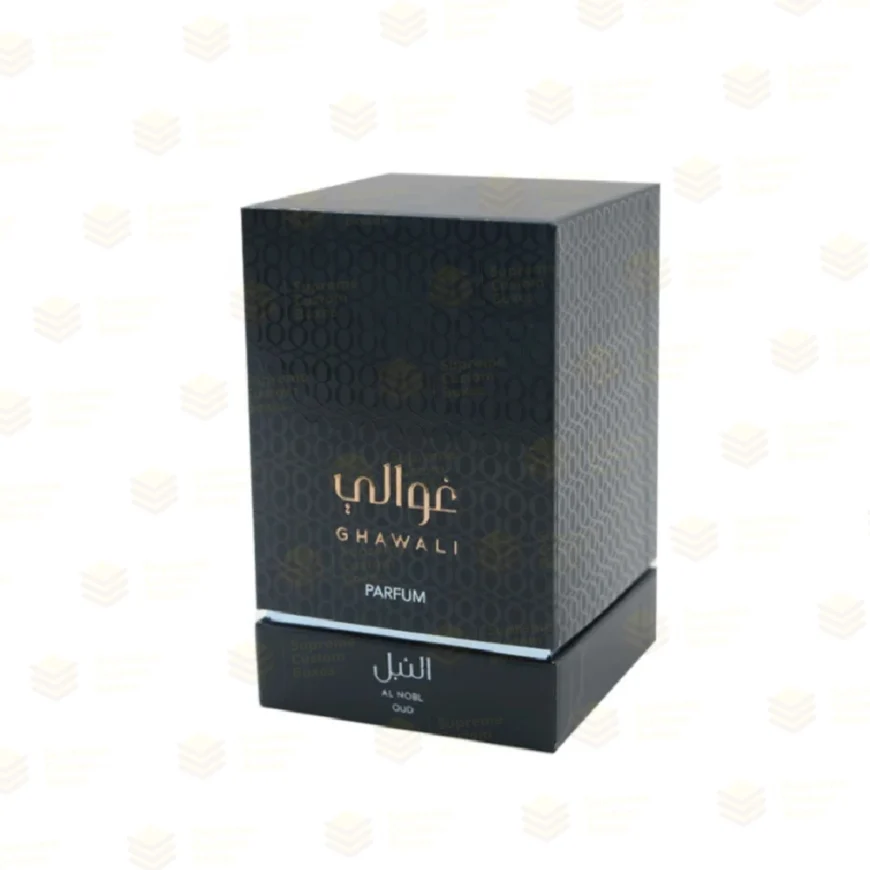

Embossed boxes for luxurious items

As a custom packaging supplier, we offer a wide range of packaging that can be embossed, debossed, hot stamped, and much more. Foil hot stamping is commonly used with embossing to give packaging boxes an opulent feel. Because of this feature, this custom embossing goes well with the packaging of luxurious items. Among many forms of premium packaging that we can create are embossed gift boxes, elegant jewelry boxes, and so on.

Benefits you get from choosing custom-printed embossed boxes

As a result of embossing and debossing, the packaging can have a luxurious, intricate appearance and feel. This indicates that extra care and effort have been put into your packaging, which can increase the customer’s desire for your product and increase their trust in you as well. You can use these processes as a green design option if you are looking for eco-friendly packaging because they do not use any additional materials. We provide our potential customers with all the options for packaging materials. You can select the material that best suits your brand from a wide range of alternatives.

These are some other perks you get for choosing embossing as a packaging option:

Display your logo to the world

In order for your logo to really stand out on your packaging and also feel unique in comparison to competitors’ packaging, embossing or debossing it is highly suitable. This will be the most effective way to make your logo stand out in comparison to your competitors’ packaging. A logo that stands out will also be more likely to be remembered, which will help develop your brand identity further.

Highlight the important stuff

There is no doubt that a three-dimensional area on your package’s surface will draw the eye naturally. If you want to highlight any important information, such as product details or contact information, embossing and debossing can be a great way to do so.

Enhancing visual appeal

The addition of texture to your packaging not only makes it visually interesting, but an embossed or debossed design can also captivate the attention of a potential buyer simply through its tactile appeal. Also, never underestimate the power of touch when it comes to packaging.

Improve the perception of the product

An intricate design process like embossing or debossing indicates to the customer that the product is of a higher quality. The more a person recognizes a product and recognizes its value, the more likely they are to buy it since they know it is of good quality. Therefore, adding embossing and debossing to a plain box can make it more appealing to the customer.

Here’s how embossing works

One of the processes known as a surface treatment in the packaging industry is embossing, which raises a specific part of the box. When packaging is handled and touched, the subtle variations in surface texture create an engaging experience for customers.

In addition, embossing can be combined with gloss effects or foil. This gives embossing more depth and allows light to bounce off the surface, attracting the attention of passersby.

Customers respond to tactile packaging elements in a retail setting, so these textured finishes like embossing and debossing are a great way to encourage interaction and achieve a sophisticated and high-end appearance. In packaging boards, embossing creates a raised area, which is commonly used to print logos or other emblems.

Quality paperboard to design embossed packaging boxes

Our business revolves around the paper from which our packages are made. Without high-quality paper, we would not be able to provide a box that meets the highest standards. As a renewable resource, it is our responsibility to take care of nature’s finite resources. We respect nature and use only material that is harmless to the surroundings. Therefore, we have strategically opted for a paperboard supplier who is committed to sustainability.

Embossing and debossing on packaging

Customers like tactile elements in packaging, so embossing and debossing are great ways to encourage interaction and make your packaging look high-end.

Depending on your brief, we can create a fully custom-made pattern with embossing, debossing, and/or a combination of the two. Alternatively, we can create standard finishes, such as leather or linen.

In terms of visual complexity, embossing adds a new dimension to your branding messages and graphics. It is typically used in packaging applications in order to enhance:

- Logos

- Text

- Artwork designs

- Watermarks

- Symbols

- Emblems

Why are boxes embossed?

In marketing and brand-building, embossing offers the following benefits:

Immediate attention and product differentiation

- Consumers receive a memorable experience

- Brand recognition and recall value gets higher

- A high benefit-to-cost ratio (excellent return on investment)

In general, embossing and debossing are great finishing techniques to elevate your branding and elevate your packaging design.

Is it expensive?

In general, the cost of embossed boxes usually includes the cost of plates and dies. However, the price will vary based on the amount of embossed area that is desired. Although the process is generally not expensive before ordering make sure you have clear artwork areas to emboss to save on your budget. Any changes to that will result in the need for extra plates, which in turn will increase the cost.