In the modern e-commerce landscape, your packaging is more than just a container; it is a strategic asset. Selecting the wrong material can lead to two major business failures: product damage during transit or a brand image that feels “cheap” to the consumer.

At Supreme Custom Boxes, we specialize in helping brands navigate the technical differences between Corrugated vs. Rigid packaging to ensure maximum protection and premium presentation.

1. Corrugated Packaging: The Engineered Choice for Durability

Corrugated material is the backbone of the global shipping industry. Unlike standard paperboard, corrugated fiberboard is a high-performance material designed to withstand vertical pressure and side-impact shocks.

The Anatomy of Strength

A corrugated sheet consists of a “fluted” medium (the wavy paper) glued between two flat liners. This structure acts like an arch bridge, distributing weight and providing a cushion.

- Why it’s great for E-commerce: It is incredibly lightweight. Since shipping carriers in 2026 use dimensional weight pricing, the lightness of corrugated material keeps your postage costs down.

- Storage Benefits: These boxes ship to you flat. You can store thousands of units in a small corner of your warehouse and assemble them only when needed.

- Customization: With modern die-cutting, we can create “Mailer” styles that tuck in perfectly, providing a secure seal without needing excessive tape.

2. Rigid Boxes: The Standard for Luxury and Value

If you are selling a high-ticket item—like jewelry, high-end electronics, or luxury cosmetics—a corrugated box might feel too “industrial.” This is where Rigid Boxes (also known as set-up boxes) come in.

The Perception of Quality

Rigid boxes are made from heavy-duty chipboard that is up to four times thicker than the average folding carton. They do not collapse or fold flat.

- Structural Integrity: Because they are “set up” at the factory, they have a solid, brick-like feel. This weight communicates “value” to the customer before they even see the product.

- Premium Finishing: Rigid boxes allow for “wrapping.” We can wrap the structural board in linen, silk-touch paper, or embossed foils. These textures are difficult to achieve on standard corrugated surfaces.

- The “Keepsake” Factor: Research shows that customers are 70% more likely to keep and reuse a rigid box for home storage, keeping your brand visible in their daily lives long after the purchase.

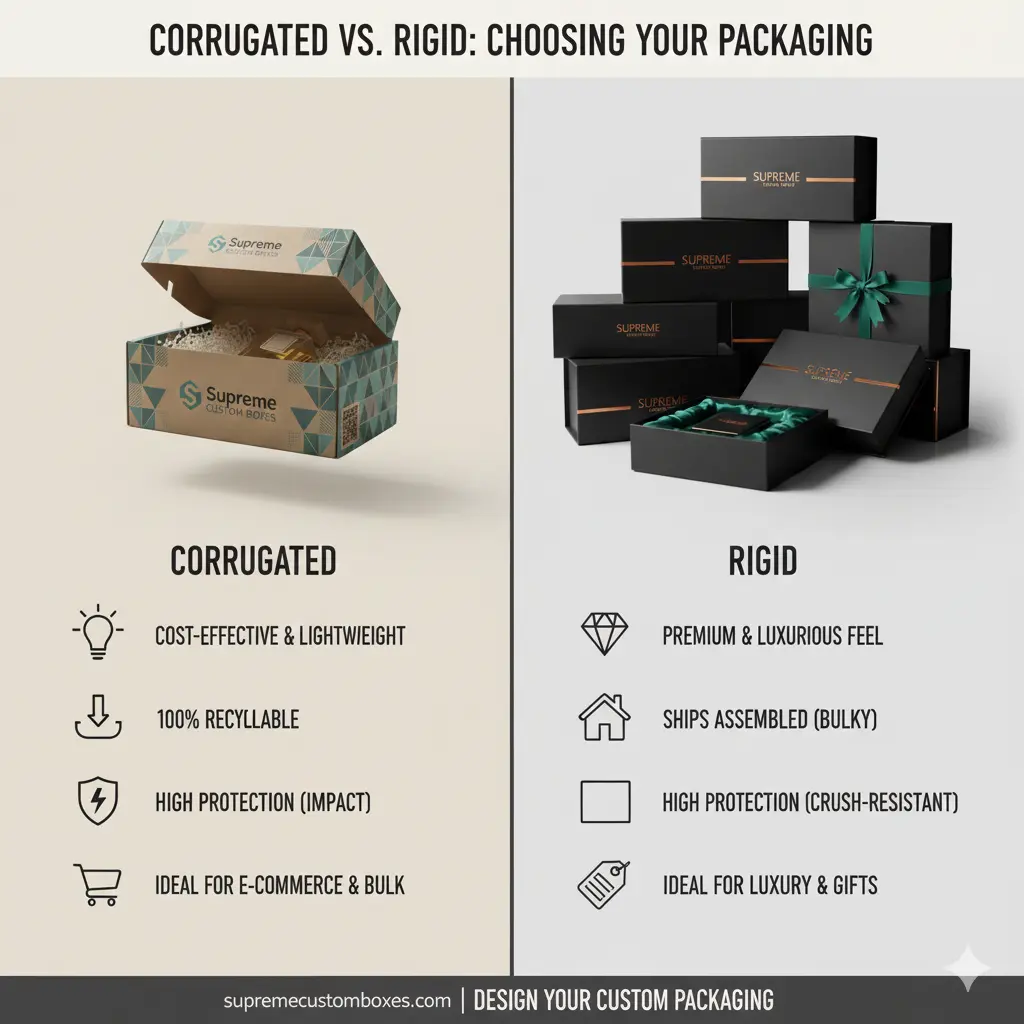

3. The Technical Comparison: At a Glance

| Feature | Corrugated Boxes | Rigid Boxes |

| Material Build | Fluted medium between liners | High-density compressed chipboard |

| Shipping Cost | Low (Ships flat and light) | High (Ships pre-assembled and heavy) |

| Protection Level | High (Best for impact/vibration) | High (Best for crush resistance) |

| Unboxing Experience | Professional/Functional | Opulent/Exceptional |

| Sustainability | 100% Recyclable | Reusable/Premium |

4. Which One Should You Choose?

Choose Corrugated If:

- You run a subscription box service and need to keep shipping costs low.

- Your products are heavy (like tools or car parts) and need the “flute” to absorb vibration.

- You have limited warehouse space and need boxes that store flat.

Choose Rigid If:

- You are selling luxury items where the packaging is part of the product.

- You want a “lifting” or “telescoping” lid experience (think iPhone box).

- Your product is small but high-value, and you want it to feel more substantial in the hand.

5. The Supreme Custom Boxes Advantage

At Supreme Custom Boxes, we don’t just take orders; we provide structural consultations. We understand that a startup has different needs than a multinational corporation.

- No Die Charges: We believe custom packaging should be accessible. By removing die and plate charges, we allow you to test different sizes and styles without a massive upfront investment.

- Free Design Assistance: Not sure if your logo will look better on Kraft or White corrugated? Our design team provides free mockups to ensure your brand looks perfect.

- Fast Turnaround: In the fast-paced world of 2026, you can’t wait months for packaging. Our streamlined manufacturing ensures your boxes are at your door in record time.

Conclusion

Choosing between Corrugated vs. Rigid packaging is a balance of budget, weight, and brand image. If you want a rugged, eco-friendly, and cost-effective solution, Corrugated is your winner. If you want to create an unforgettable, high-end “moment” that justifies a premium price point, Rigid is the only way to go.

Ready to see the difference for yourself? Get a Free Quote today, and let our experts help you design a box that does more than just hold a product—it builds a brand.